Factory price front Shock Absorber A2123233300 A2123233400 For Mercedes-Benz 21

Front Rear shock absorber for Mercedes w251 v251 air suspensio

High quality Front And Rear Air Bellow w221/W220 air suspension For Mercedes Be

Factory Price Gas Shock With ADS Rear Auto Air Suspension for Mercedes W253/W292

W205 Auto Suspension Parts Front Shock Absorber Strut For Mercedes Benz W205

Supply condition:

1. Hard Chrome Plated4. Dehydrogenation & Tempered

Bend Test According to customer requirement

Application:

Piston rod is mainly used in hydraulic pneumatic, engineering machinery, automobile manufacture with the piston rod, guide pillar plastic machinery, packaging machinery, printing machinery, roller, textile machinery, transportation machinery with axis, linear motion with the linear optical axis.

Specification:

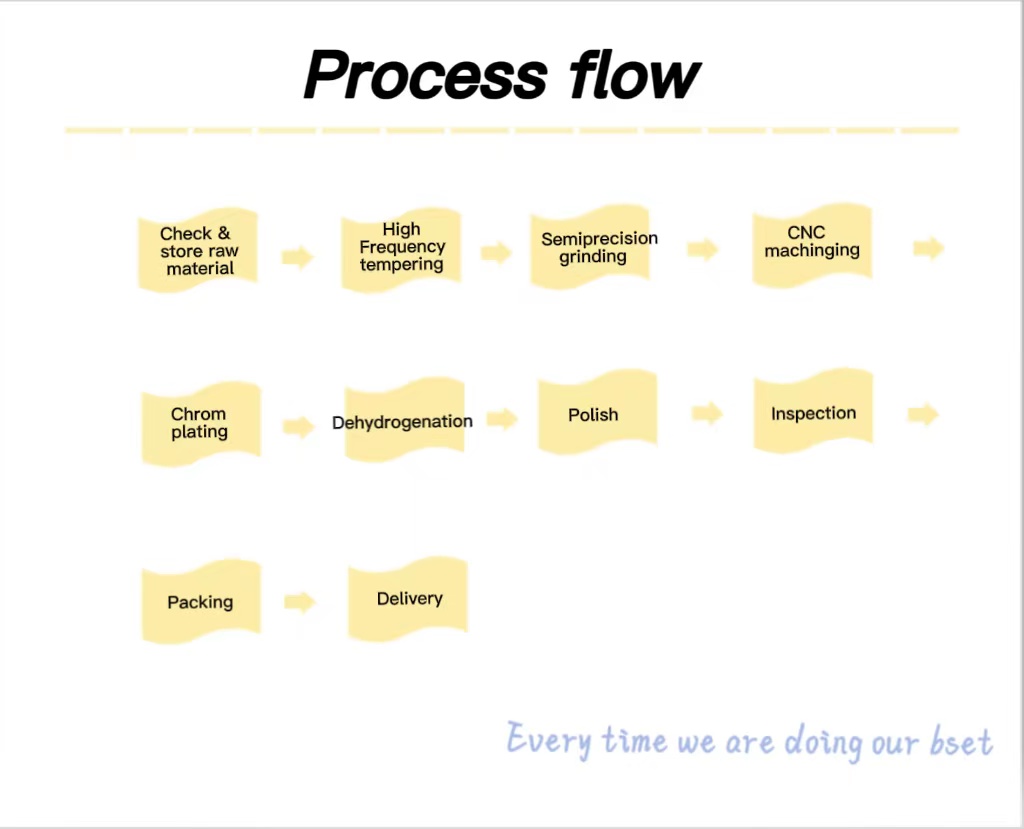

Process Flow.

1). Process flow of hydraulic piston rod.

Connecting rod using 35 steel, processing technology: cold-drawn forming a turning a continuous medium frequency induction hardening, a cylindrical grinding, a fine grinding cylindrical a fine grinding cylindrical shearing section.at finishing a plating chromium to hydrogen tempering shearing section.at fine grinding.In order to improve the surface quality and corrosion resistance of piston rod, super finishing process was added before chrome plating.

2). Piston rod plating process.

Inspection before plating - pack hanging fixture - chemical degreasing, electric lift oil - water - activation pickling - water washing- the moment, the piston rod chromium plating, recycling water - water washing - unloading hanging fixture - inspection

Manufacturing process description:

1. Hydraulic shear cutting

2. CNC machining + additional broaching and milling operations

3. Induction hardening at a range of different frequencies and powers

4. Rotary straightening

5. Proportionally servo controlled CNC grinding

6. Leading edge technologies for hard chromium,

7. Dehydrogenation and tempering

8. Wet polish and superfinish polish with 100% surface condition control

9. Export Packaging

Packing Of Piston Rod

Each rod will be oil treatment first , then separate by layer and layer , one by one .Each small box use VCI bag to protect from rust , then box into wooden pallet .The weight and size can be made according to customer requirement .

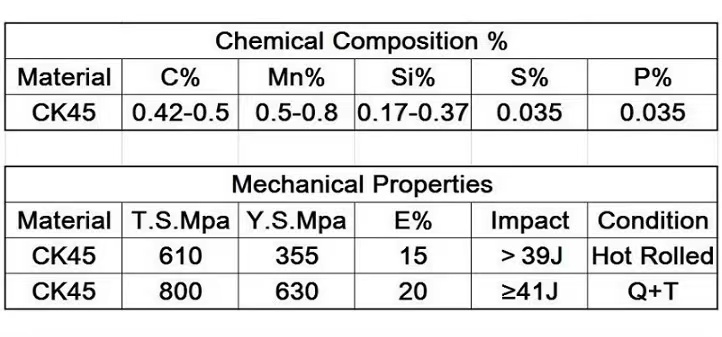

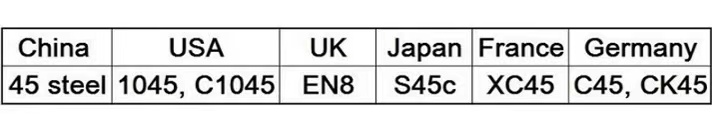

Metal material

Intrduction of factory

Ver todas las especificaciones

Ver todas las especificaciones

Ver todas las especificaciones